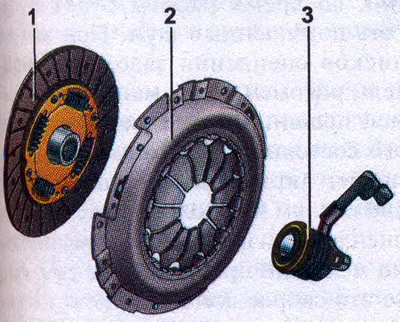

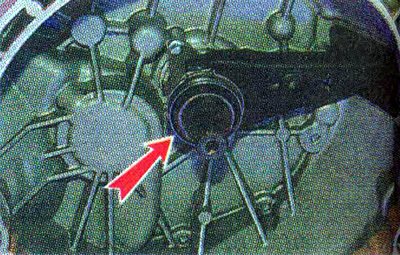

Clutch details: 1 - driven disk; 2 - pressure plate assembly (basket); 3 - clutch release cylinder assembly with release bearing

On a car with a manual transmission, the clutch release drive is hydraulic.

The clutch consists of a basket (pressure plate assembly) and slave disk. The basket is a steel casing in which the pressure plate is installed. From the side of the casing, the disk is pressed by a pressure spring of the diaphragm type. The clutch basket is attached with six bolts to the flywheel. A driven disk is installed between the pressure plate and the flywheel.

Friction linings are riveted to two sides of the driven disk. To dampen torsional vibrations at the moment the clutch is engaged, a damper with coil springs is built into the driven disc. The hub of the driven disk enters splined engagement with the input shaft of the gearbox.

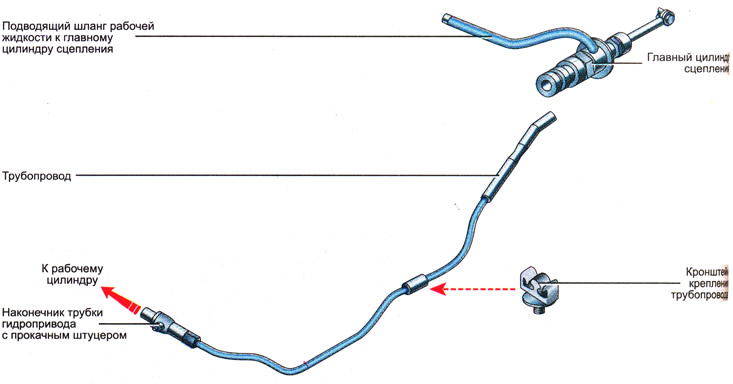

Clutch release hydraulic drive consists of master and slave clutch release cylinders connected by a pipeline.

Clutch hydraulic

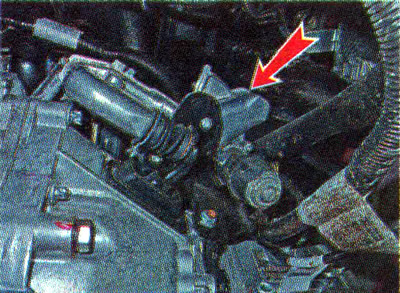

Through the pipeline, pressure is supplied to the working cylinder, which in turn transmits force to the central diaphragm spring of the clutch through the clutch release bearing. The clutch slave cylinder is assembled in a single block with a release bearing (spare parts catalogs use both of these names to designate a part) and installed in the clutch housing.

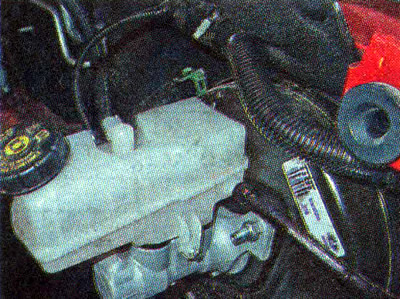

Brake fluid is used as the working fluid in the hydraulic clutch. It enters the clutch master cylinder through a hose from the brake master cylinder reservoir. For this, a branch pipe is made on the left side of the tank.

The hydraulic fluid in the clutch release system must be changed regularly in accordance with the maintenance plan (see «Maintenance plan»).

Malfunctions of the master and slave cylinders of the clutch include: wear of the cuffs of the clutch master cylinder; leakage of working fluid at the junction of pipes and fittings and from under the cuffs of the pistons of the cylinders.

Comment. In the event of a leak in the working cylinder, there will be leakage of brake fluid from below from under the clutch housing. The presence of oil leaks in the same place is caused by wear of the gearbox input shaft oil seal. You should also check the clutch hydraulic hose and tube to make sure they are free from cracks, cuts, or other damage. We replace defective parts.

Correct operation of the clutch release hydraulic actuator is possible only if there is no air in the system, due to which the clutch may not completely disengage. As a result, gear shifting will be difficult or impossible. Air can get into the system when the fluid level in the reservoir of the main brake cylinder drops below the permissible limit, as a result of a violation of the tightness of the connections.

The tightness must be restored by replacing damaged parts. To remove air, it is enough to pump the clutch release hydraulic actuator. The bleeder fitting is made in the tip of the hydraulic drive tube.

On automated manual transmission 2182 (AMCP), instead of a hydraulic clutch release mechanism, an electric drive mechanism is installed.

The electric drive acts directly on the clutch fork. The clutch release fork rests on a support with a ball tip. When the fork is turned, the force is transmitted to the pressure spring petals through an angular contact ball bearing (release bearing). The bearing is put on the clutch release clutch, through which it contacts the clutch release fork.

Due to the lack of play in the clutch release drive, the clutch is constantly pressed against the pressure spring petals, while the release bearing is continuously working. The bearing is lubricated for its entire service life. The clutch release clutch moves along the guide sleeve, put on the input shaft of the gearbox and attached to the clutch housing with three bolts.

A worn release bearing will make excessive noise during operation. When replacing clutch discs, the manufacturer recommends that the release bearing be replaced, regardless of its condition. This is justified if the mileage of the car was about 100 thousand km or more. But if the clutch disc has worn out over a significantly lower mileage (30-40 thousand km), then this is most likely the result of improper operation of the car. In this case, it is likely that the release bearing has retained a sufficient resource for further operation. However, when replacing the clutch discs, the condition of the bearing should be checked: if during rotation its outer ring sticks, play is felt or noise is heard, the release bearing must be replaced.